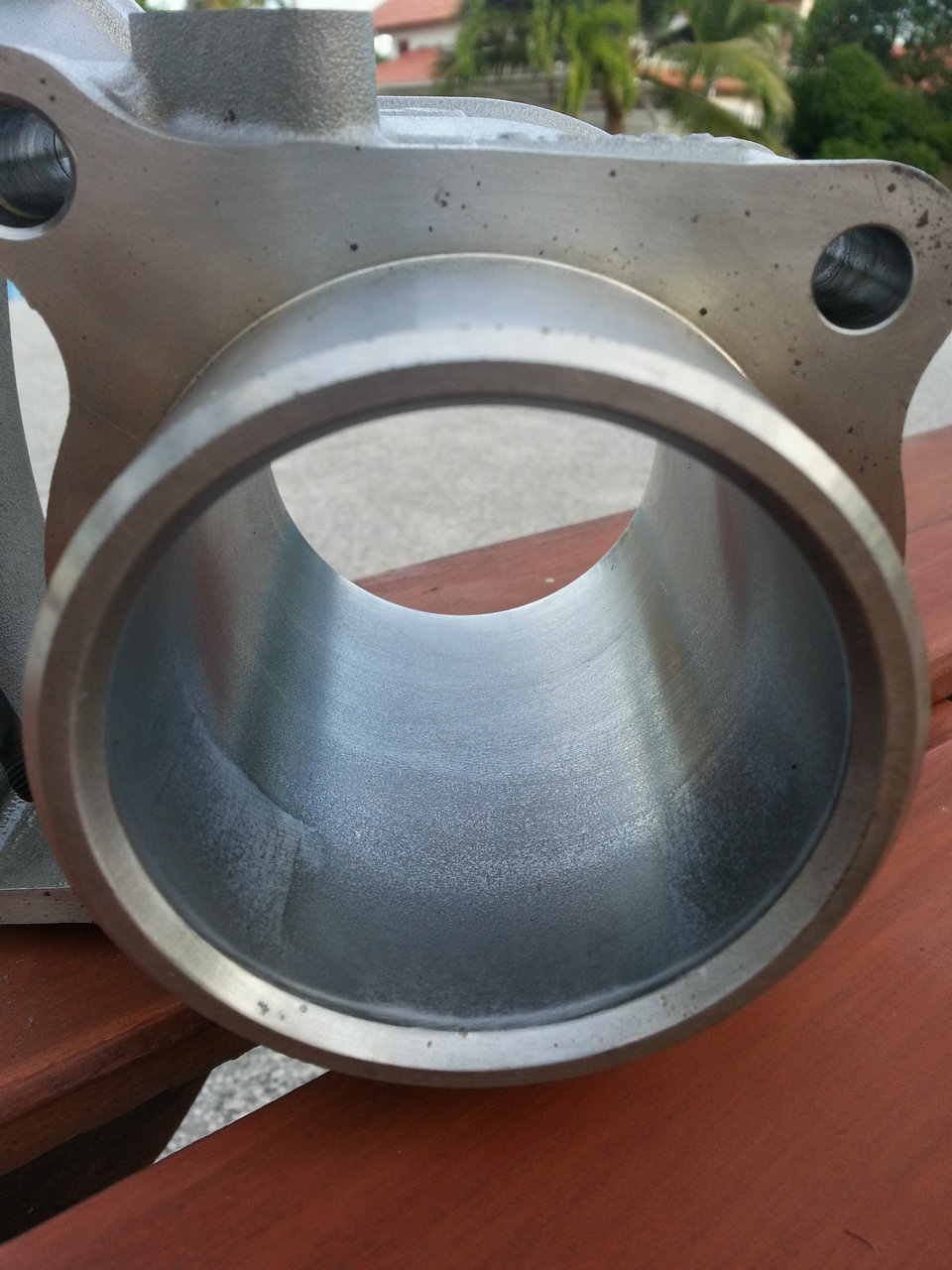

KLX 250 cylinder de-glazing

#1

I've got 2009 KLX 250 with 70000 km here in Thailand, recently decided to do a top-end rebuild, got a new piston and rings.

Found a big bunch of deposits on the piston and the valves. Intake valves have crystal-like deposits, which I managed to clean up, while exhaust valves faces are heavily pitted, ordered replacements.

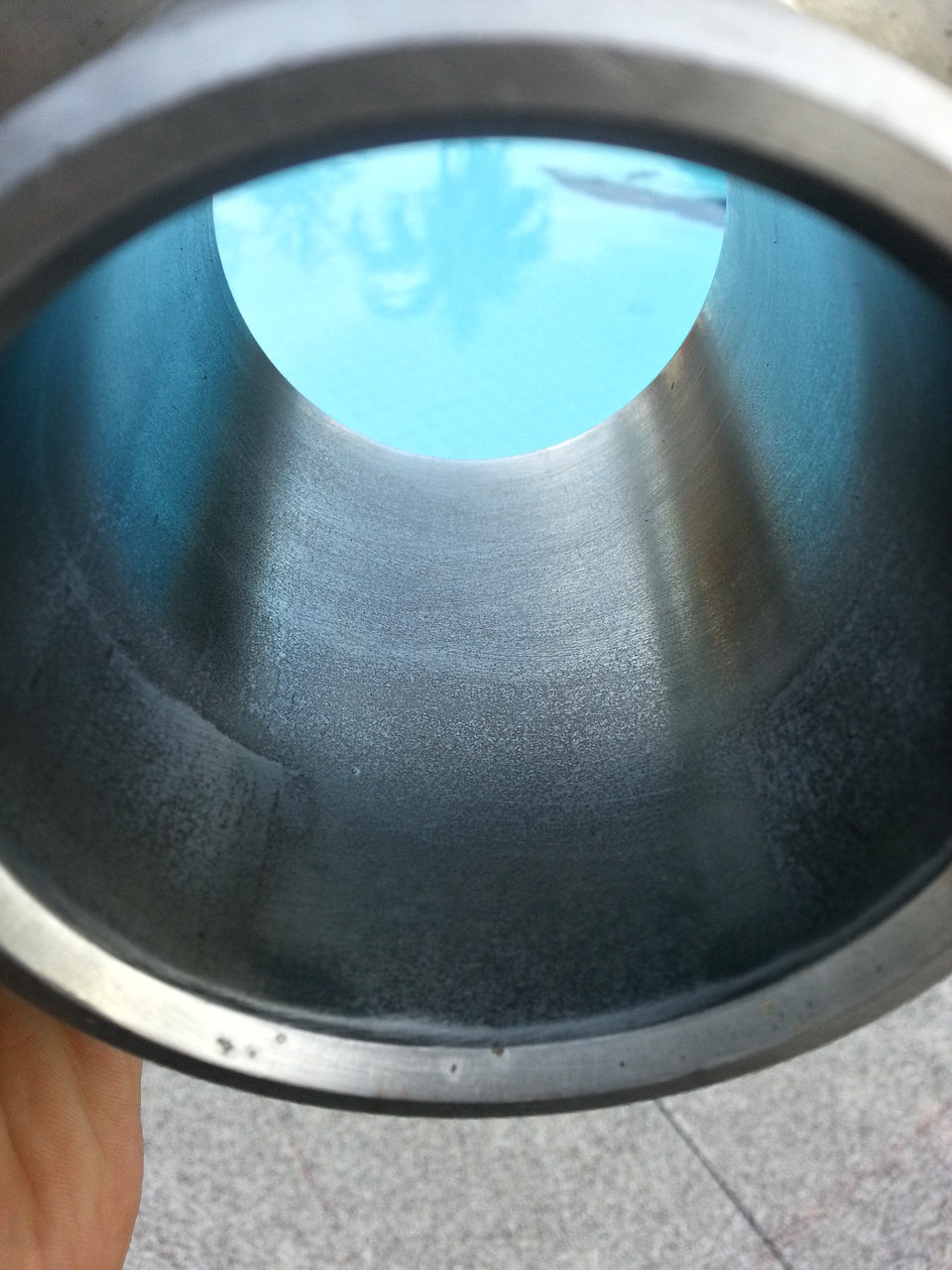

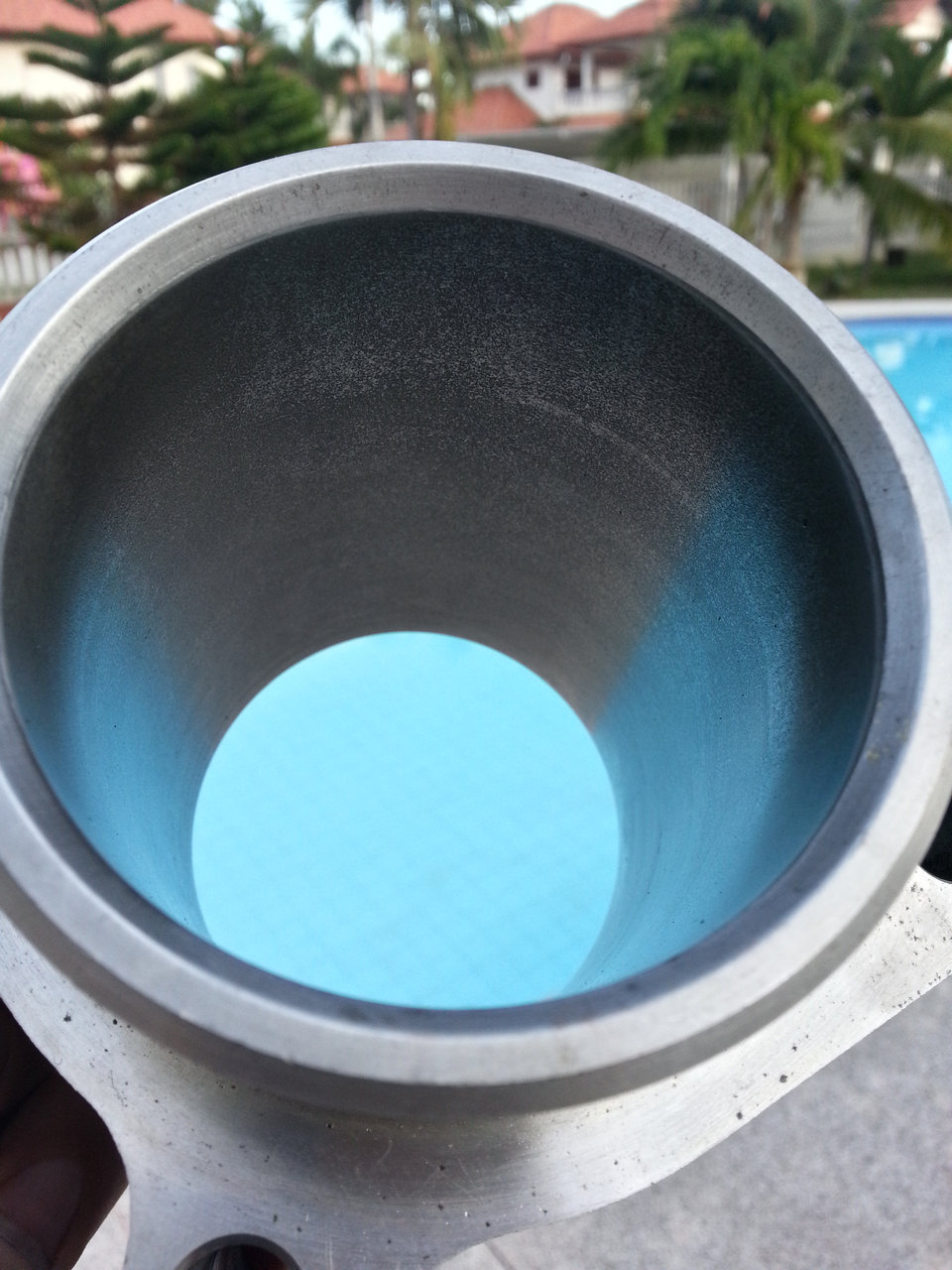

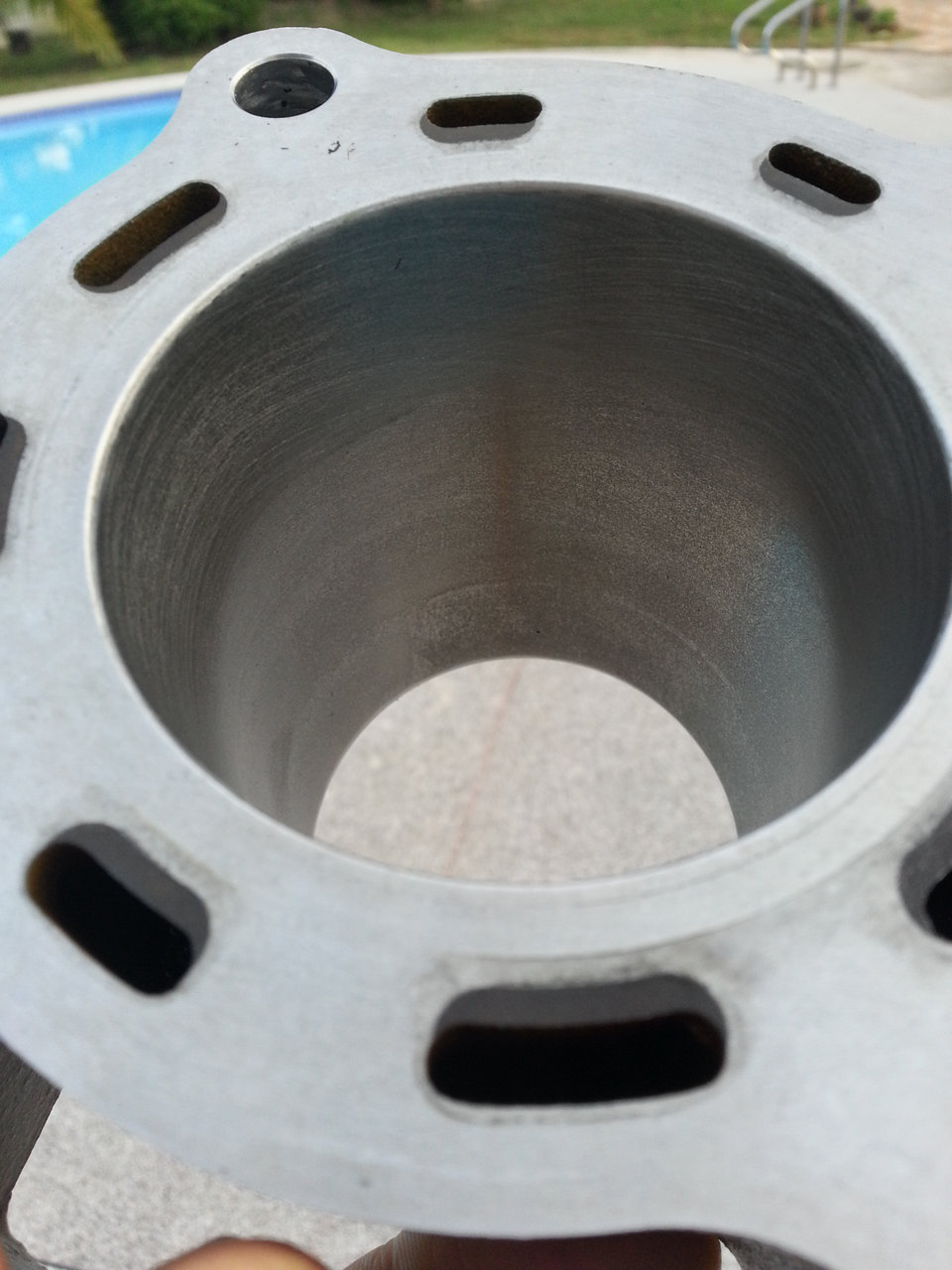

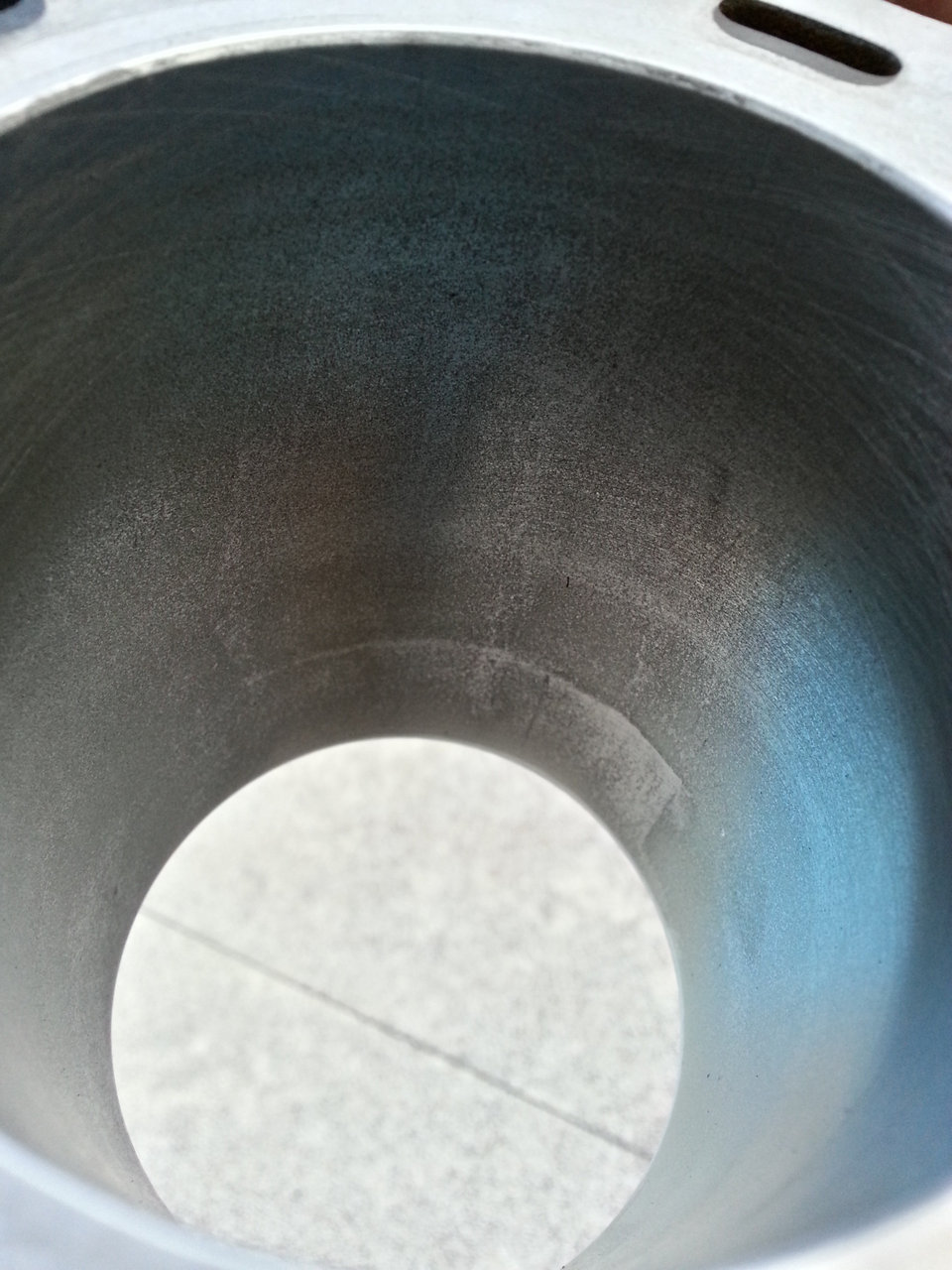

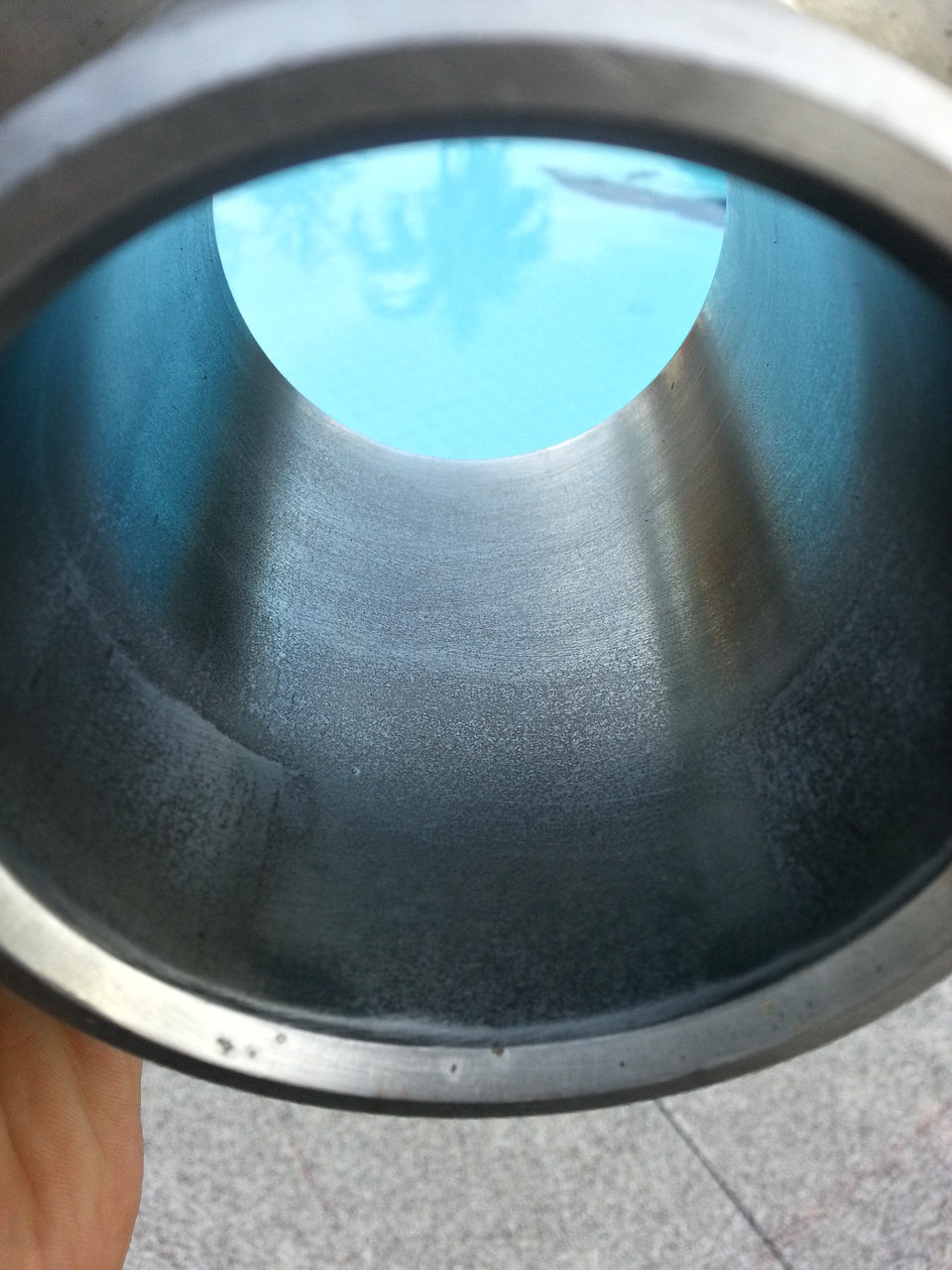

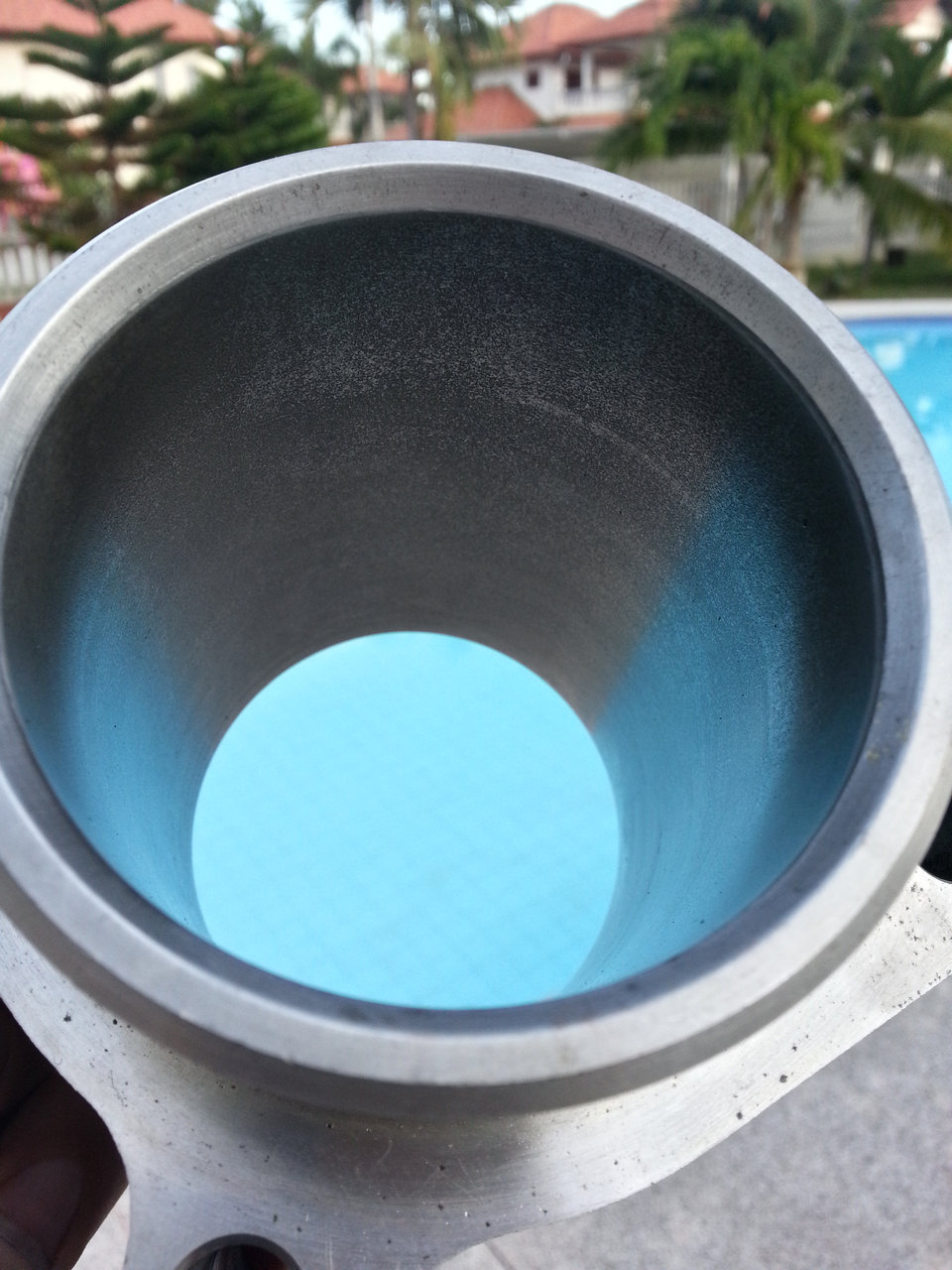

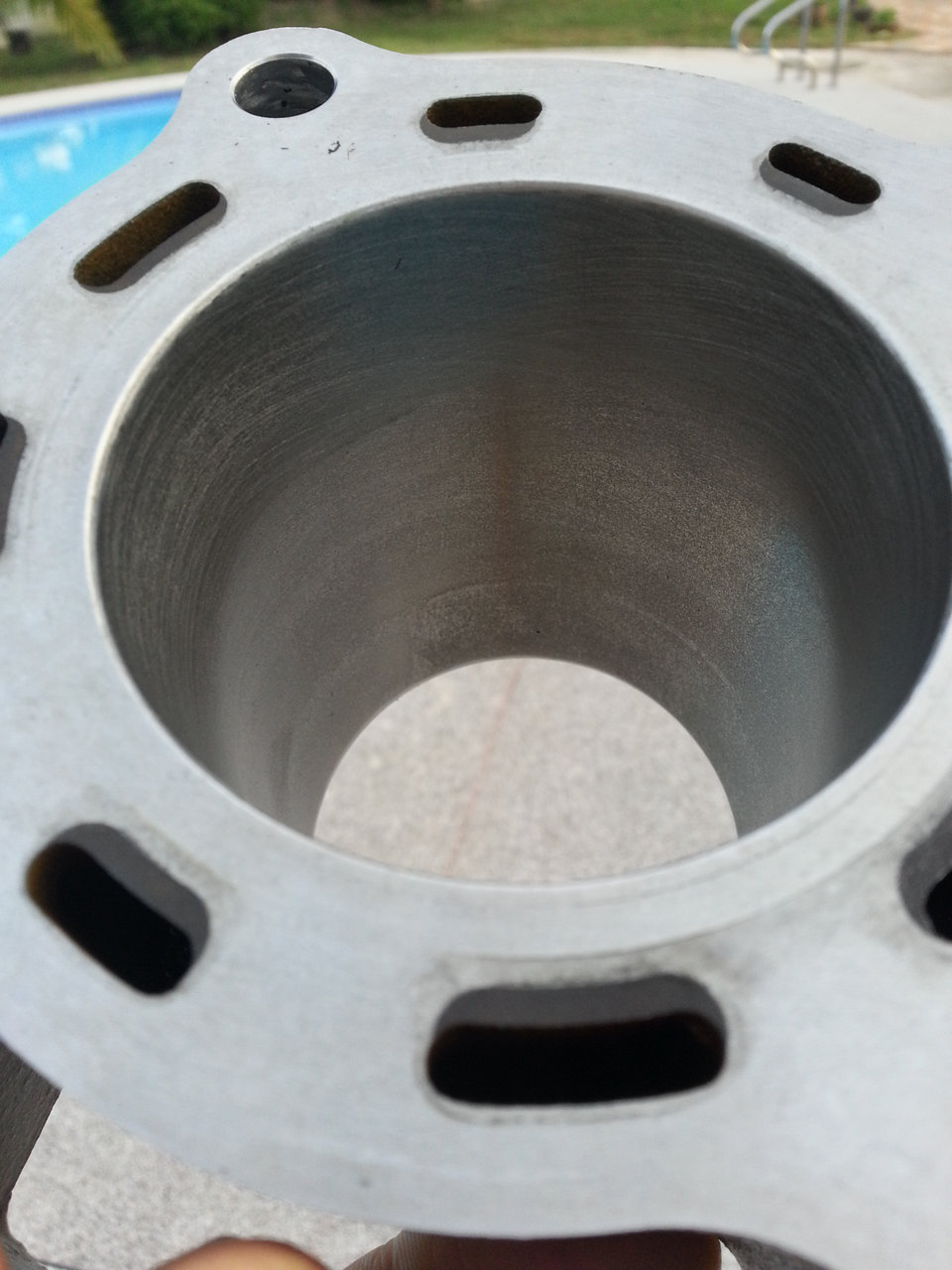

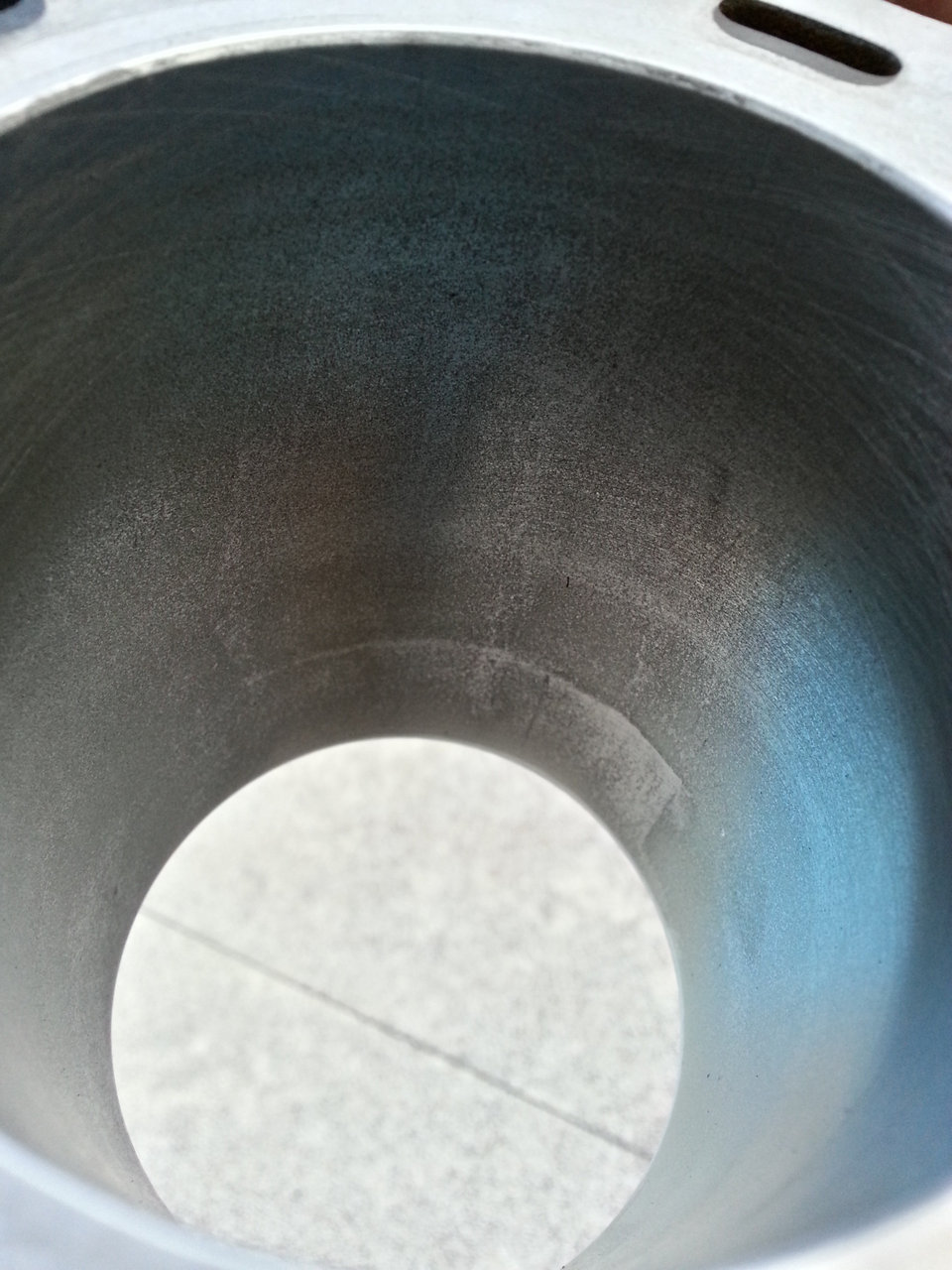

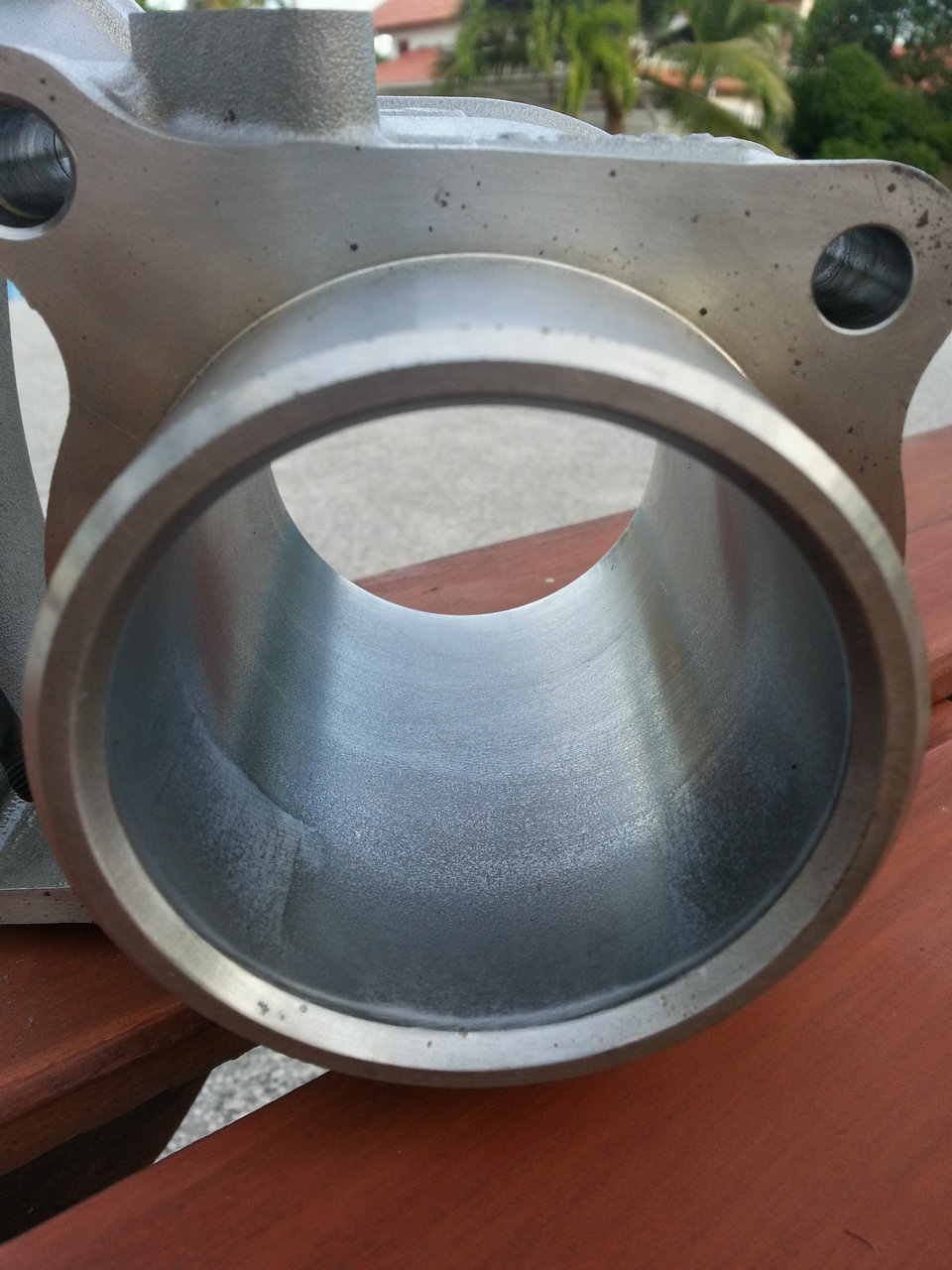

Following what I read in various forum discussions, tried to deglaze the cylinder using green scotch-brite pads (from the supermarket's cleaning section), and later 320 grit sandpaper. Unfortunately, I'm not sure what it should look like - before and after, but there are some areas which definitely look not uniform and neither scotch-brite nor sandpaper doing anything to them. Took it to an official Kawasaki dealer in Kui Buri, a medium-sized town in Thailand, asked their mechanic to clean up my cylinder, one day later he gave me back the cylinder with some honing marks, but still not uniform areas clearly visible. He said Thai people would use the cylinder like that, and if I want to hone more (or bore&hone? my Thai is not so good, he used the word that means "cut"), the fit of the piston will become loose. I don't have any experience with coated aluminum cylinders, please advise? Does it look like the plating is damaged, or does it look like hard-to-remove glazing?

Another question is - the cylinder to head mating surface looked not that clean with some small black spots, wife took a scotch-brite pad to it while I was not looking, small black spots (some kind of pitting?) remained however there is now a bunch of shallow scratches. The head gasket is multi-layer steel, I've read these gaskets require pretty smooth surface finishing (somebody mentions mirror finish), am I in trouble? A good machine shop is hard to find in here... On the other hand, the service manual mentions in the section about checking head for warpage, if warp is present but less than the service limit, repair the head by rubbing on emery paper secured to a surface plate (first No 200, then No 400). From what I've found, green scotch-brite is 600 grit so are these scratches harmless? On my head, though, there already was one scratch (not caused by scotch-brite) which is a little bit deeper, I can catch my fingernail on it a little bit. Should it be repaired with the aforementioned emery paper method?

Really hoping to get some feedback, guys, I'm anxious to put the engine back without answers to these questions.

PS One of the pictures show a quick-and-dirty valve removal tool I made from some 3/8" PVC pipe - cut a couple of slots with a dremel and cleaned up with dremel and file.

Found a big bunch of deposits on the piston and the valves. Intake valves have crystal-like deposits, which I managed to clean up, while exhaust valves faces are heavily pitted, ordered replacements.

Following what I read in various forum discussions, tried to deglaze the cylinder using green scotch-brite pads (from the supermarket's cleaning section), and later 320 grit sandpaper. Unfortunately, I'm not sure what it should look like - before and after, but there are some areas which definitely look not uniform and neither scotch-brite nor sandpaper doing anything to them. Took it to an official Kawasaki dealer in Kui Buri, a medium-sized town in Thailand, asked their mechanic to clean up my cylinder, one day later he gave me back the cylinder with some honing marks, but still not uniform areas clearly visible. He said Thai people would use the cylinder like that, and if I want to hone more (or bore&hone? my Thai is not so good, he used the word that means "cut"), the fit of the piston will become loose. I don't have any experience with coated aluminum cylinders, please advise? Does it look like the plating is damaged, or does it look like hard-to-remove glazing?

Another question is - the cylinder to head mating surface looked not that clean with some small black spots, wife took a scotch-brite pad to it while I was not looking, small black spots (some kind of pitting?) remained however there is now a bunch of shallow scratches. The head gasket is multi-layer steel, I've read these gaskets require pretty smooth surface finishing (somebody mentions mirror finish), am I in trouble? A good machine shop is hard to find in here... On the other hand, the service manual mentions in the section about checking head for warpage, if warp is present but less than the service limit, repair the head by rubbing on emery paper secured to a surface plate (first No 200, then No 400). From what I've found, green scotch-brite is 600 grit so are these scratches harmless? On my head, though, there already was one scratch (not caused by scotch-brite) which is a little bit deeper, I can catch my fingernail on it a little bit. Should it be repaired with the aforementioned emery paper method?

Really hoping to get some feedback, guys, I'm anxious to put the engine back without answers to these questions.

PS One of the pictures show a quick-and-dirty valve removal tool I made from some 3/8" PVC pipe - cut a couple of slots with a dremel and cleaned up with dremel and file.

#2

I can't recall the exact medium and hone material that is required to deglaze a plated cylinder, but I don't think sandpaper was one of them. You have to use materials that are specifically compatible with plated cylinders. That's not a steel bore.

#4

From the pics, I don't see any major boogers on the bore, but I'm not so sure that sandpaper is recommended for deglazing. Here's the deal...honing of any kind is used because you can manipulate a pattern into the bore...technique that leaves the correct pattern even at the microscopic level. That's just about impossible to do with sandpaper which delivers little uniformity in its overall contact with the bore. On plated cylinders, the usual rule is that if you can still see much of the cross-hatch pattern in the cylinder walls, you just clean the surface with a solvent.

Have you installed a new ring into the empty cylinder to see how the gap compares to spec...or mic'd the cylinder?

Have you installed a new ring into the empty cylinder to see how the gap compares to spec...or mic'd the cylinder?

#5

If the bore is plated or treated, I wouldn't do too much to it, unless there was a gouge.

I wouldn't think a few pits in the top machining would be any problem. I used some copper gasket sealant for the head gasket, it covers pretty good.

I wouldn't think a few pits in the top machining would be any problem. I used some copper gasket sealant for the head gasket, it covers pretty good.

#6

I'd use it as it looks now. If I'm not mistaken, the coating looks pretty good. Give it a thorough cleaning to remove any stuck/embedded grit.

Ideally you want to remove the glazed areas as well as install a pattern, but the form of pattern is often the subject of debate. Make sure the ring end gap is in spec, use the piston to get it level and treat the rings with care, expanding just enough to install onto the piston.

Ideally you want to remove the glazed areas as well as install a pattern, but the form of pattern is often the subject of debate. Make sure the ring end gap is in spec, use the piston to get it level and treat the rings with care, expanding just enough to install onto the piston.

Last edited by Angier; 09-30-2014 at 11:10 PM.

#10

Not sure of the material Kawasaki uses but if it's a silicon carbide (nikasil) then the material is usually less than 0.005" thick so there isn't much to work with-need to micrometer the bore. The other issue with Nikasil is that it's very hard and a standard hone won't cut it-you have to use diamond honing stones to get it to size.